Real science. Real progress.

AlgaZen builds photobioreactor systems that treat brewery wastewater, capture CO₂, and produce high-value bioproducts — simultaneously. A complete A-to-Z solution for industrial sustainability.

US brewery wastewater market

CO₂ captured per kg biomass

More biomass productivity

US breweries addressable

BOD reduction achieved

The US brewing industry generates 3–7 barrels of wastewater per barrel of beer. With BOD levels reaching 3,000–5,000 mg/L, this high-strength effluent overwhelms municipal treatment systems. Breweries pay $47–50 per 1,000 gallons for disposal — averaging $150,000–200,000 per year. And beer production generates 1.3 tonnes of CO₂ per gallon.

States are tightening regulations with heavy surcharges for BOD/TSS exceeding 300 mg/L. The industry needs a solution that treats wastewater, captures carbon, and creates value — not just costs.

3–7 barrels of toxic wastewater generated per barrel of beer produced

$200K/yr3,000–5,000 mg/L biochemical oxygen demand — up to 30× residential sewage

30× sewageSignificant CO₂ from fermentation and energy use across the brewing process

1.3 t CO₂/galHeavy surcharges and fines for BOD/TSS exceeding 300 mg/L discharge limits

$6.5–10B mktWe don't just treat wastewater — we transform it. Microalgae perform a biochemical conversion more valuable than simple disposal: CO₂ + wastewater + sunlight becomes biomass, oxygen, and profit.

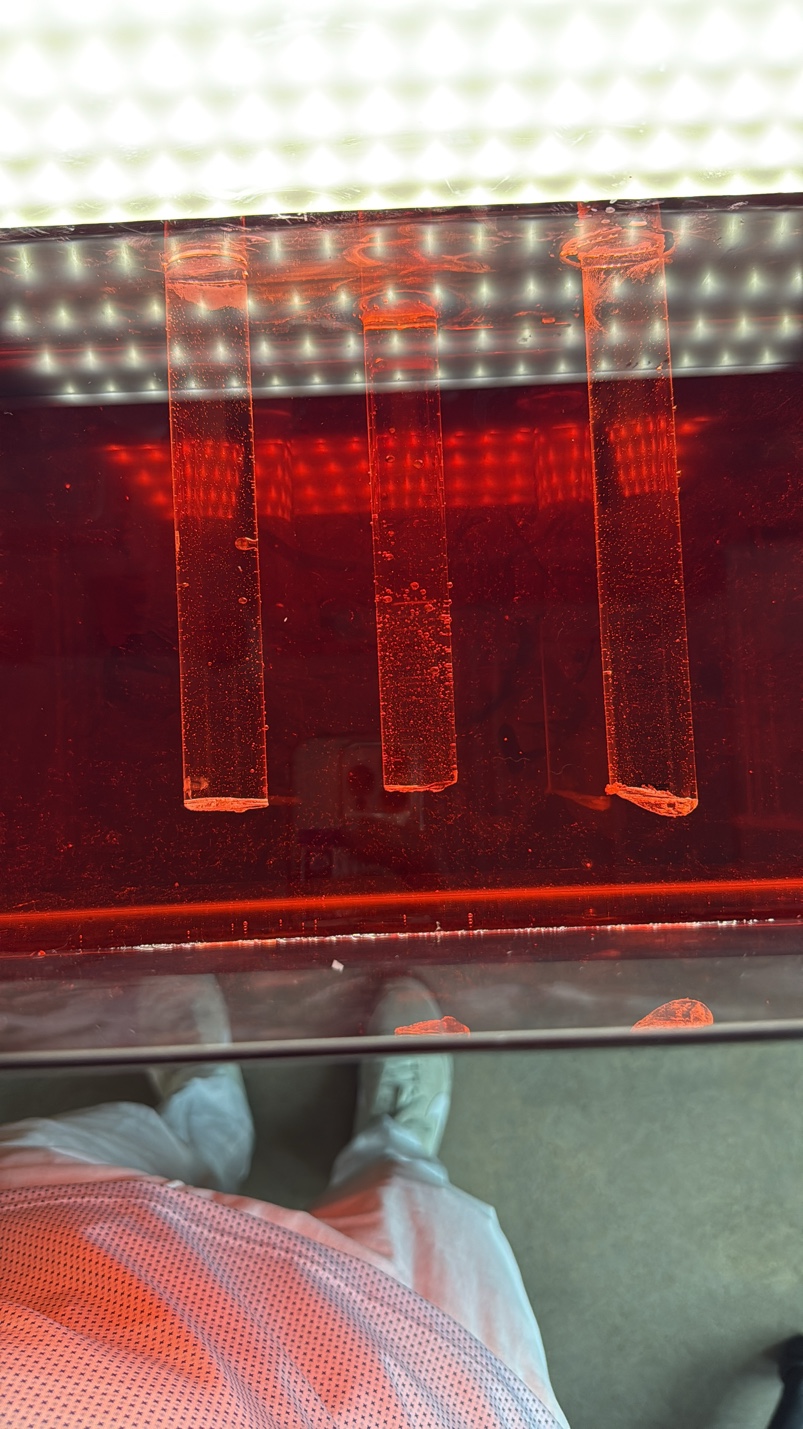

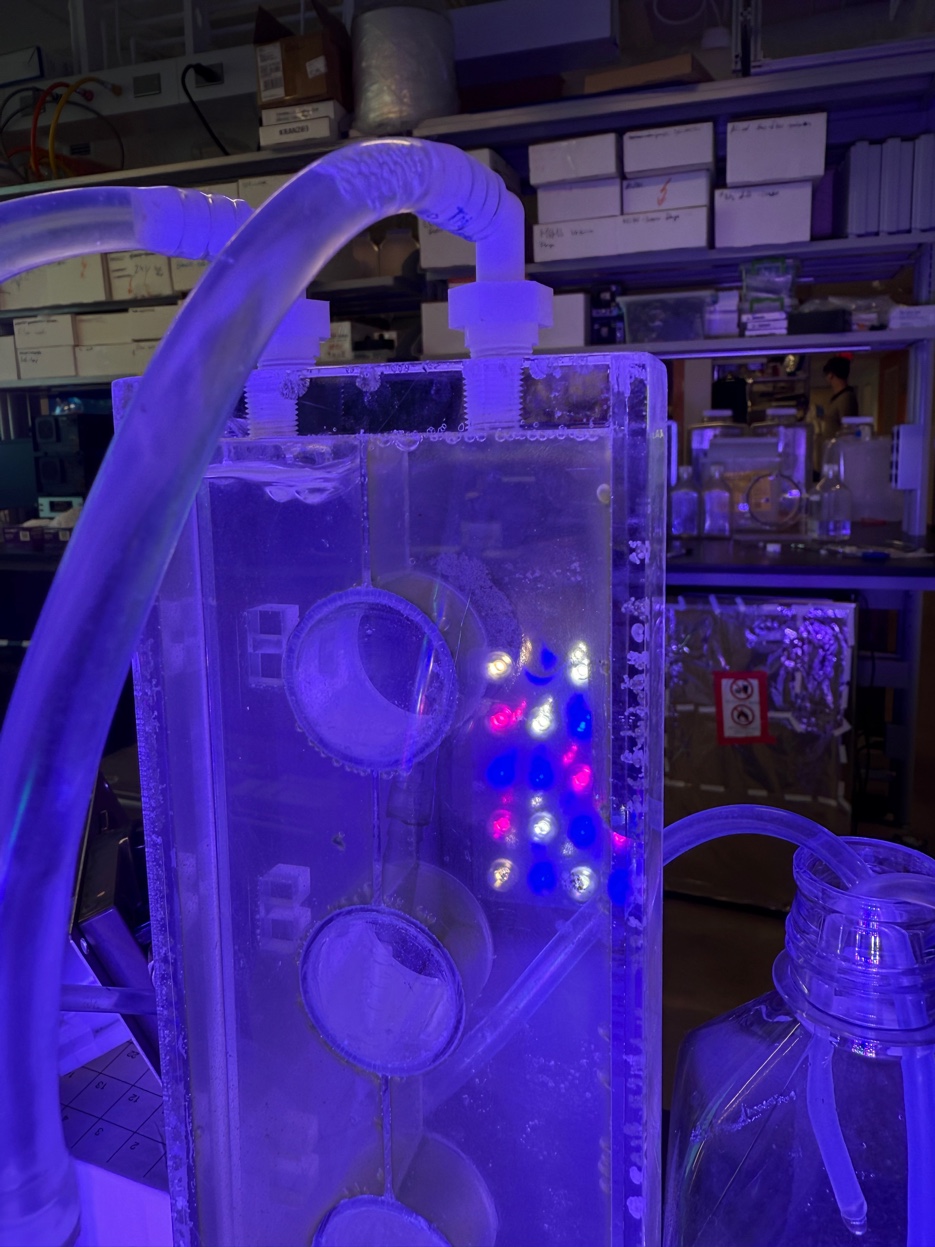

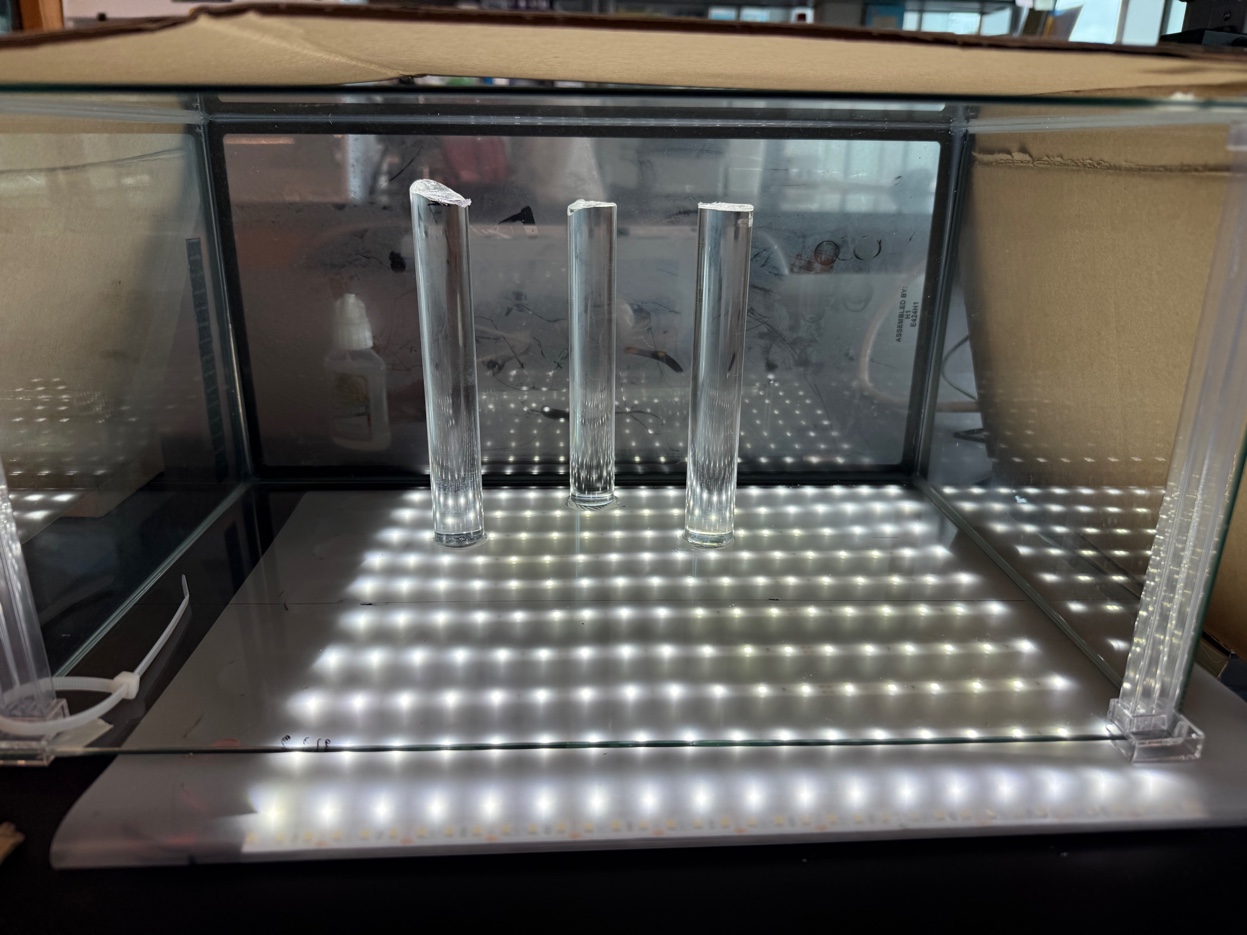

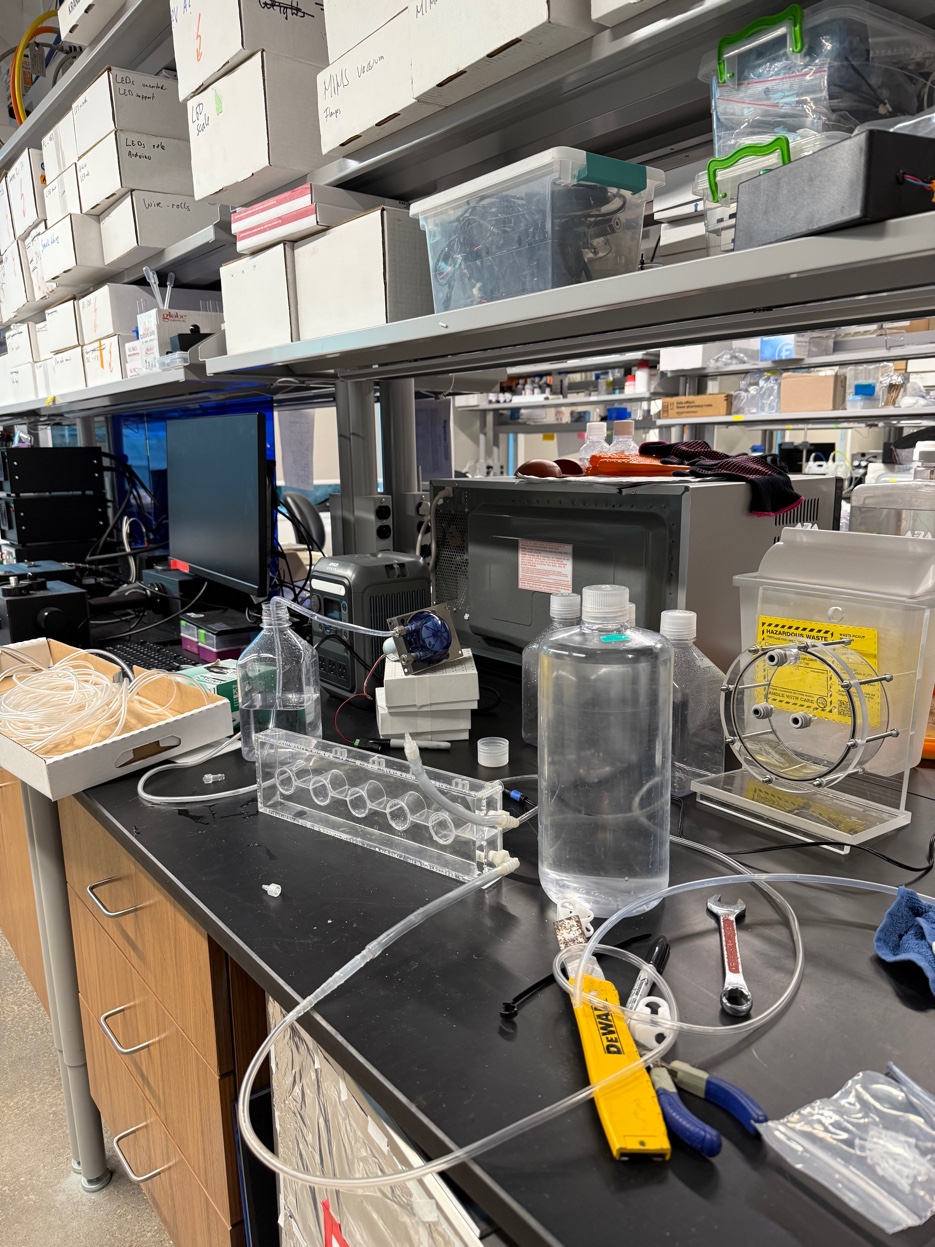

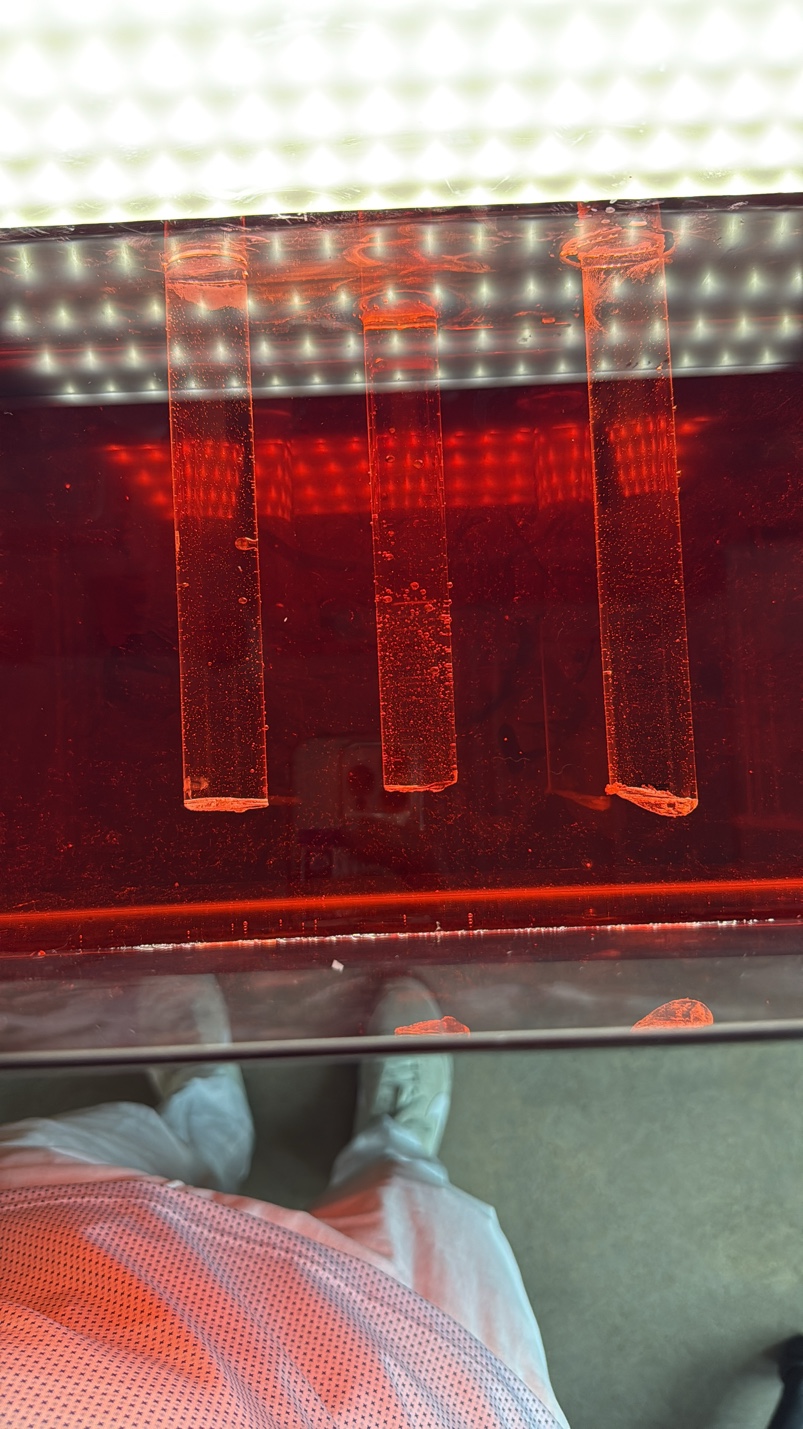

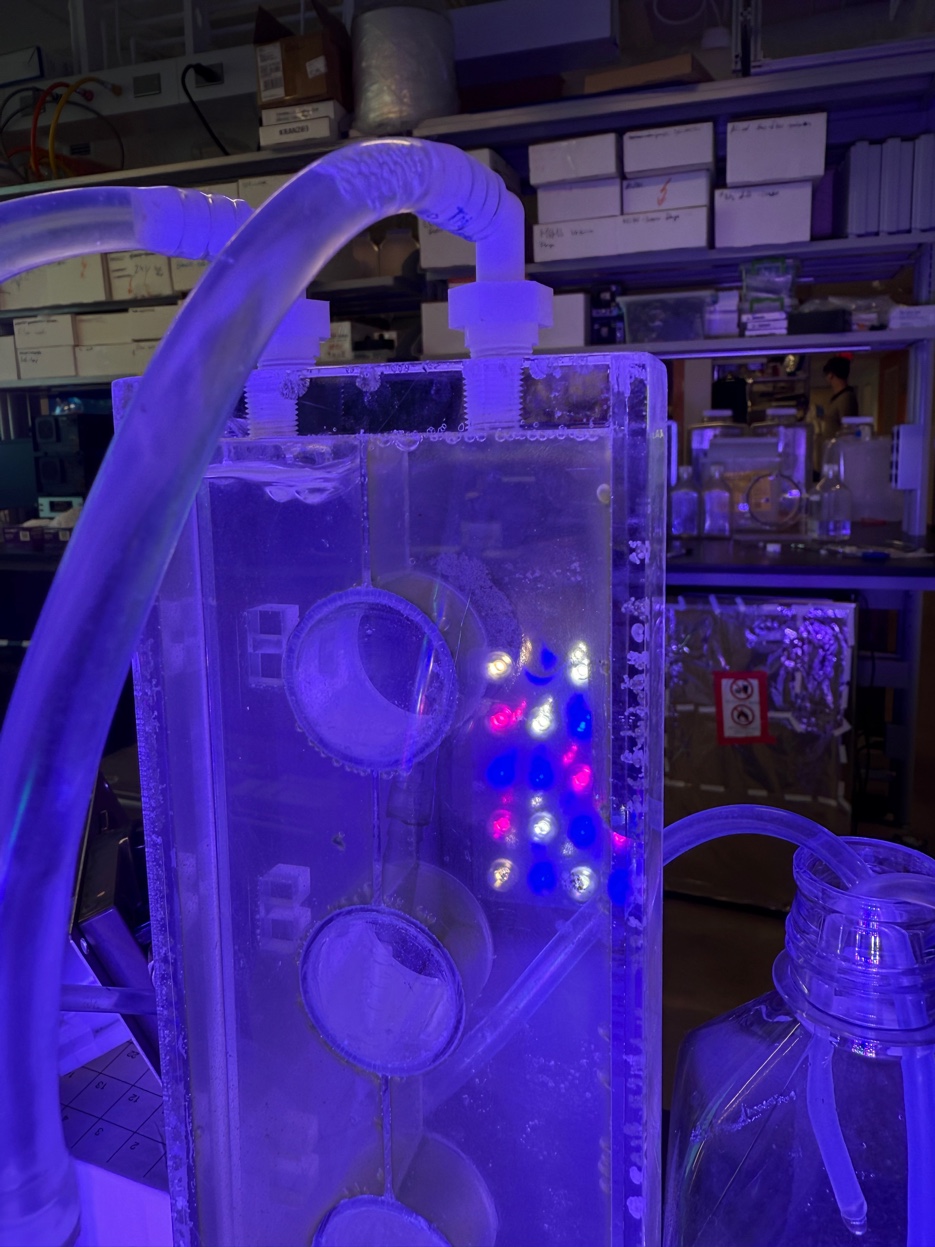

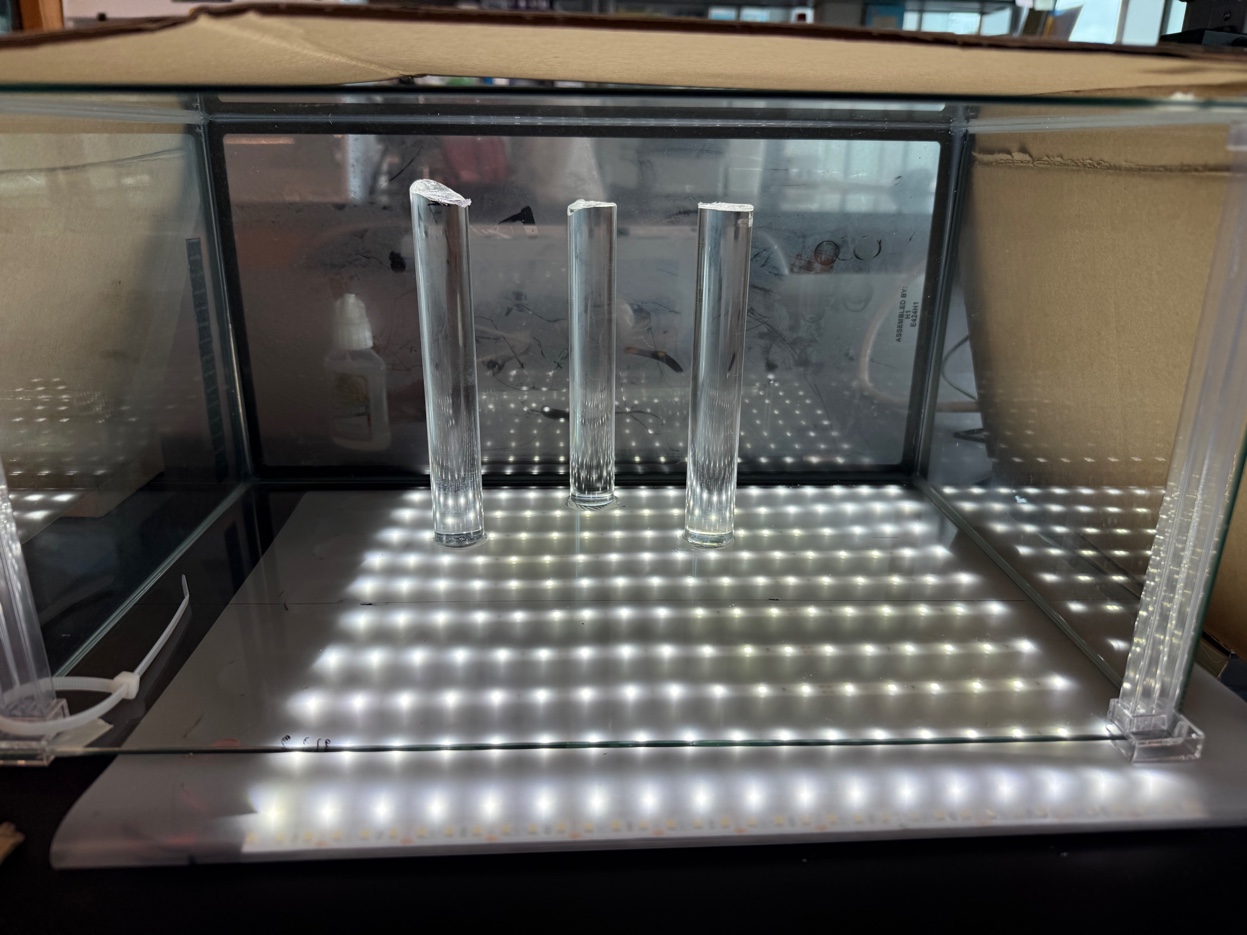

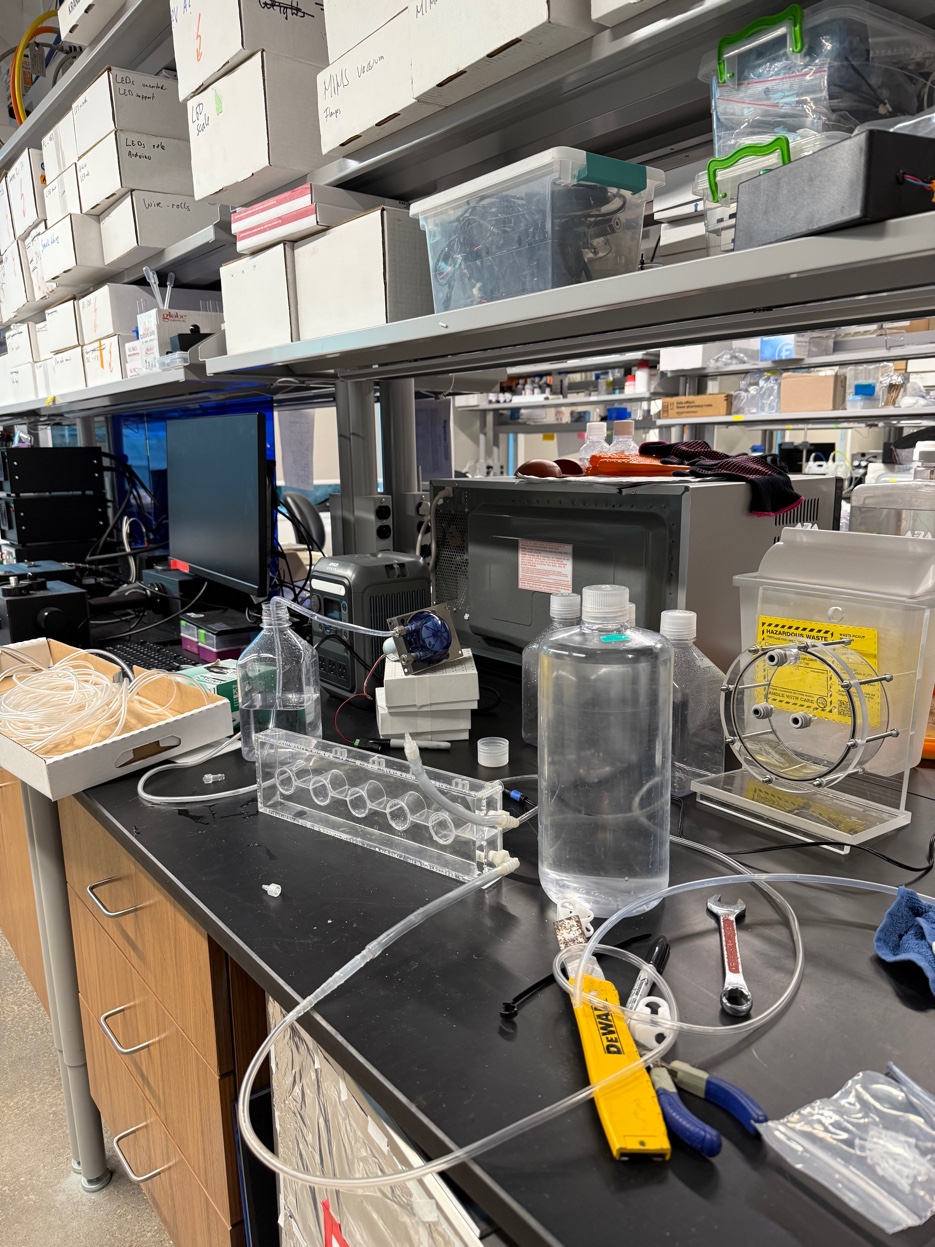

Our PBR features internal acrylic light-guide rods with aspherical lenses that distribute photosynthetically active radiation uniformly throughout the reactor volume. This eliminates the dark zones that limit growth in conventional systems — delivering 27% more biomass productivity and 26% more CO₂ capture than industry-standard flat-panel PBRs.

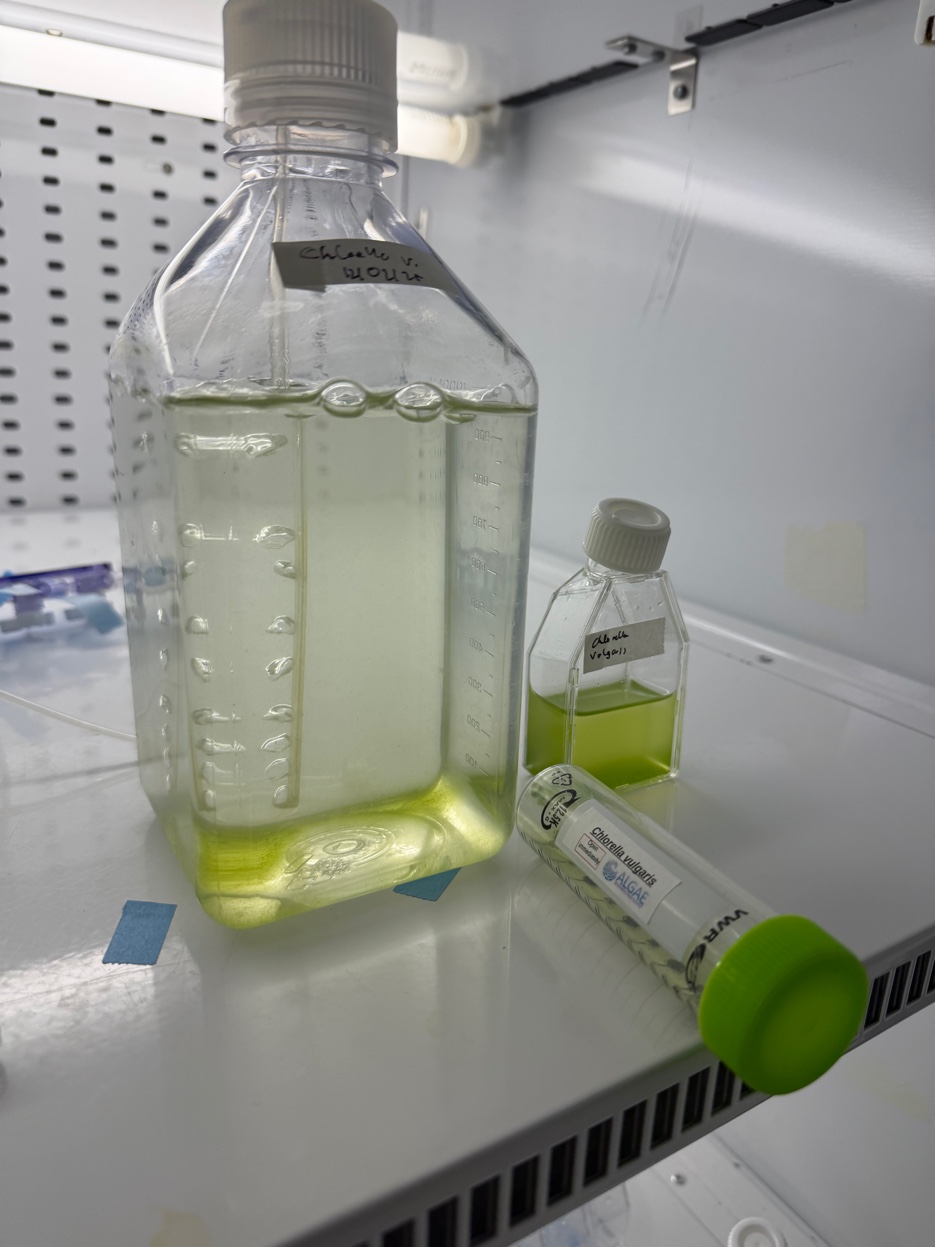

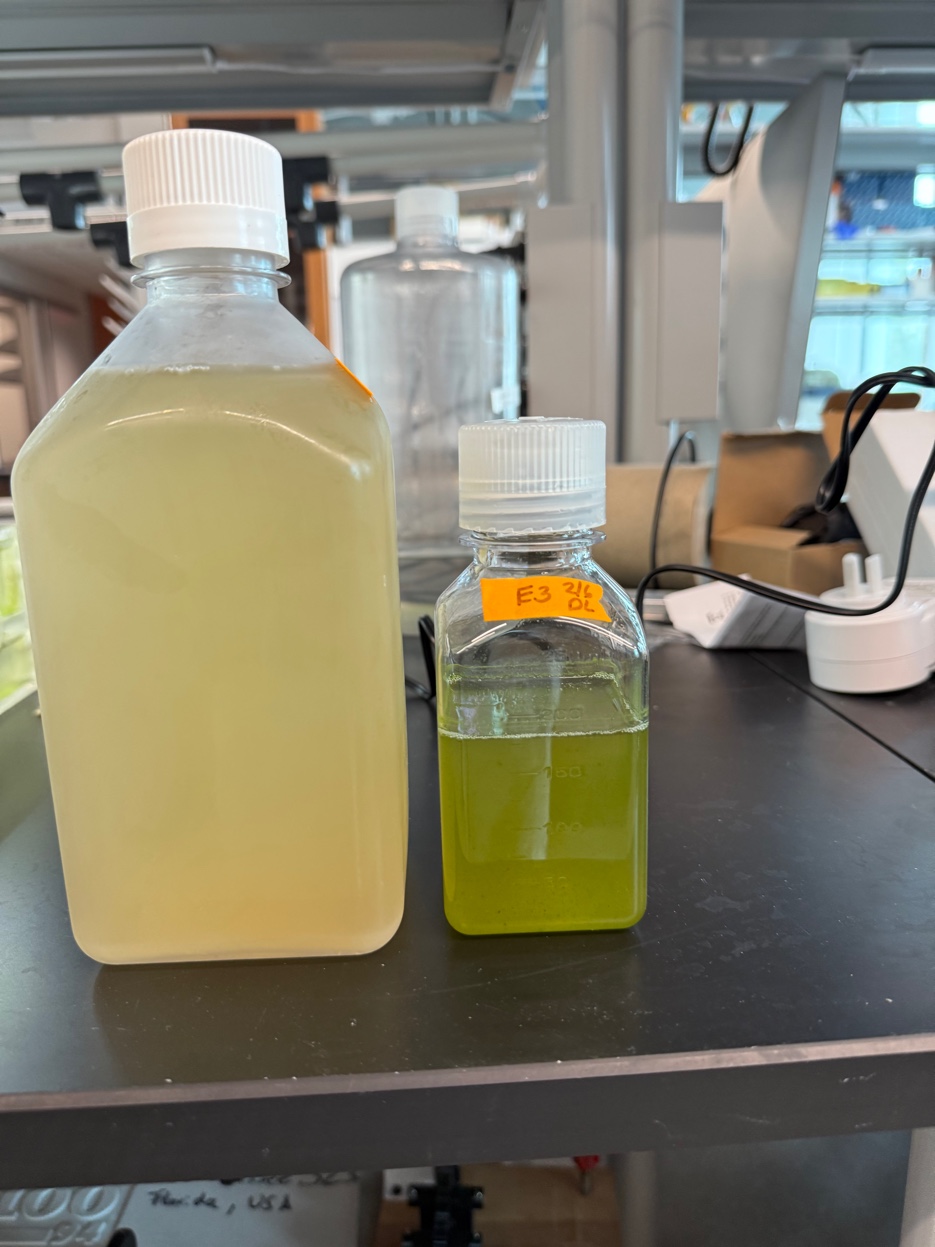

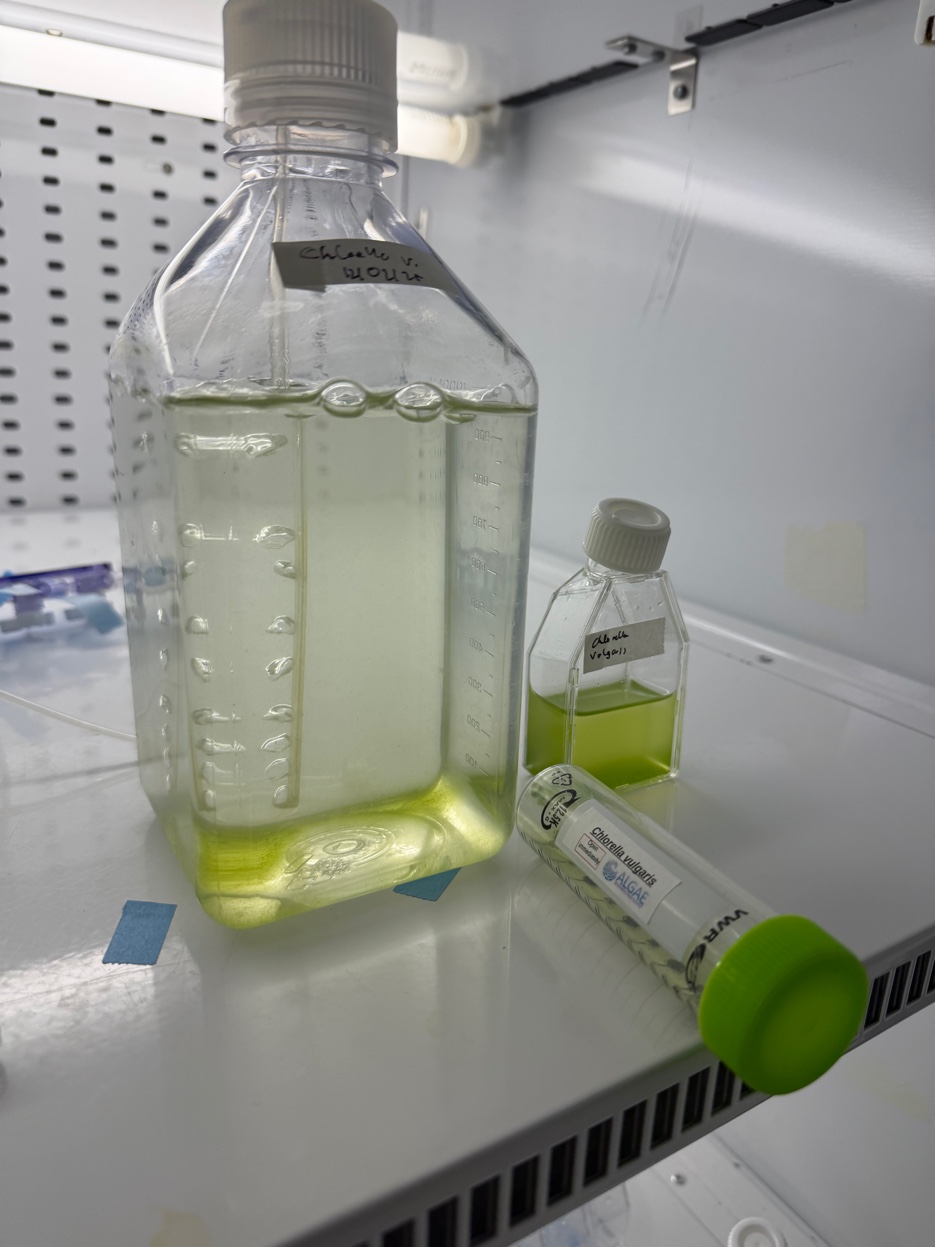

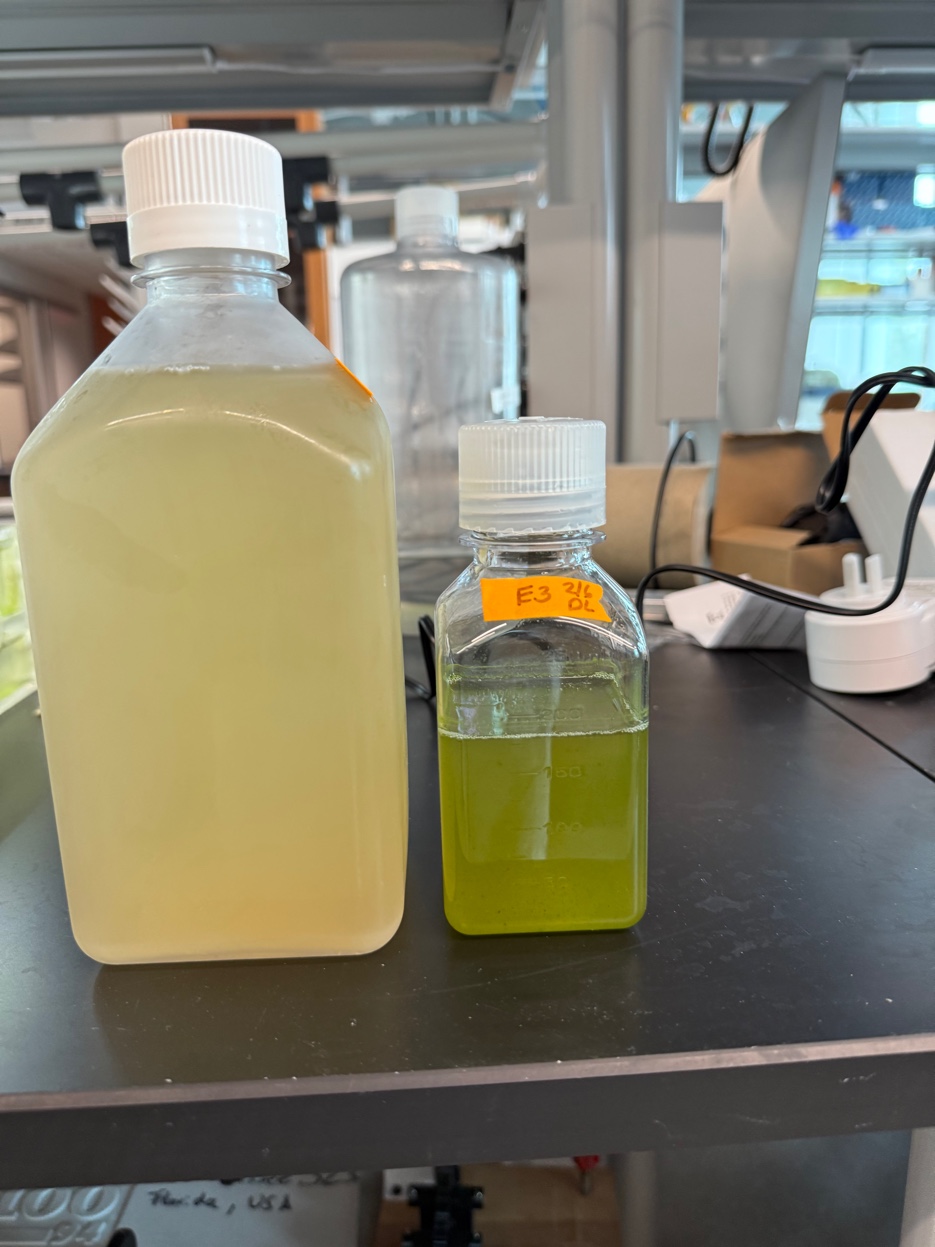

Patent PendingBrewery wastewater is loaded with nitrogen (30–60 mg/L TN), phosphorus (5–15 mg/L TP), and organic carbon (300–800 mg/L COD) — equivalent to commercial algal growth media at zero cost. Our algae consume these nutrients as food, reducing BOD by up to 80%, removing 60–90% of nitrogen and phosphorus, and simultaneously fixing 1.83 kg CO₂ per kg biomass through photosynthesis.

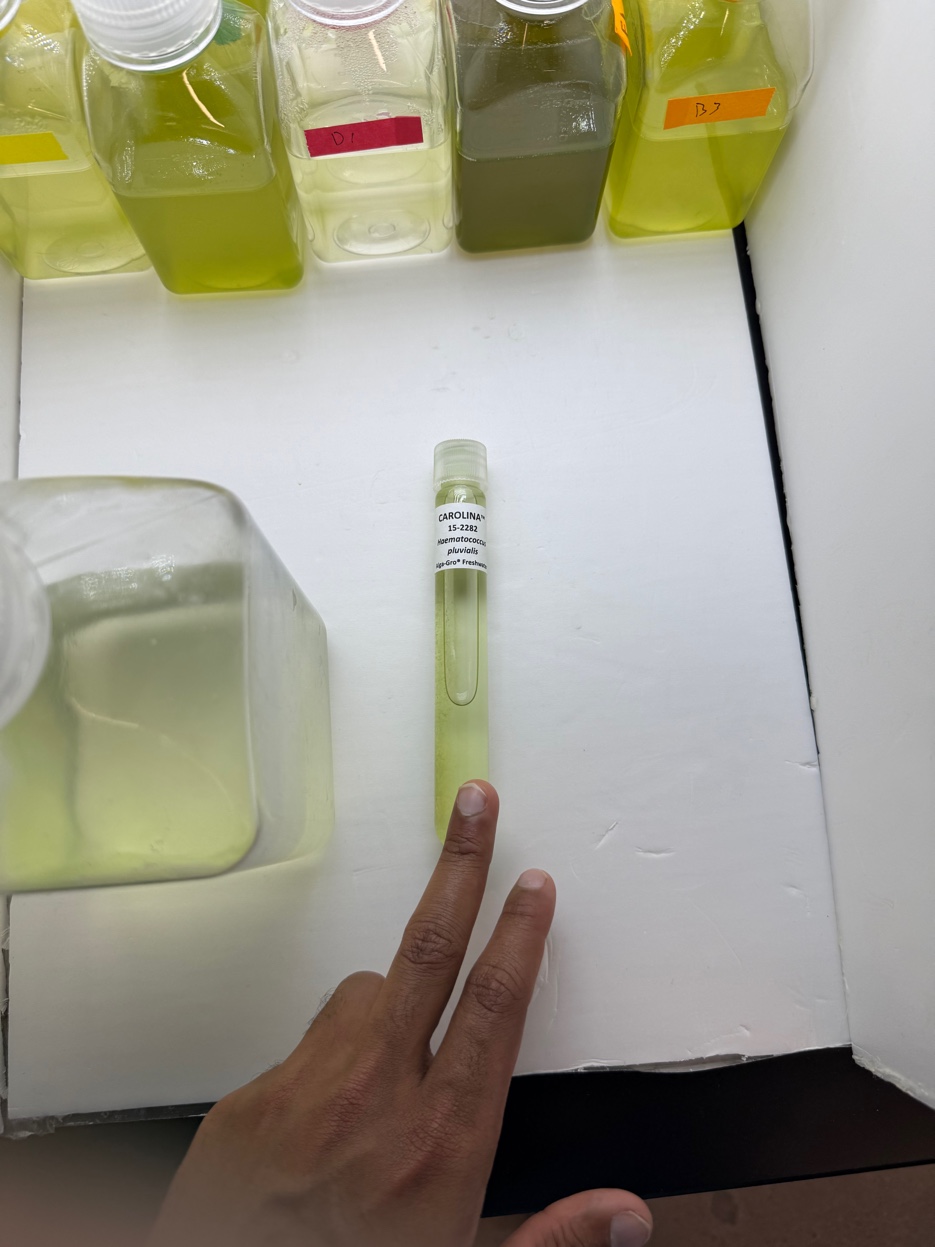

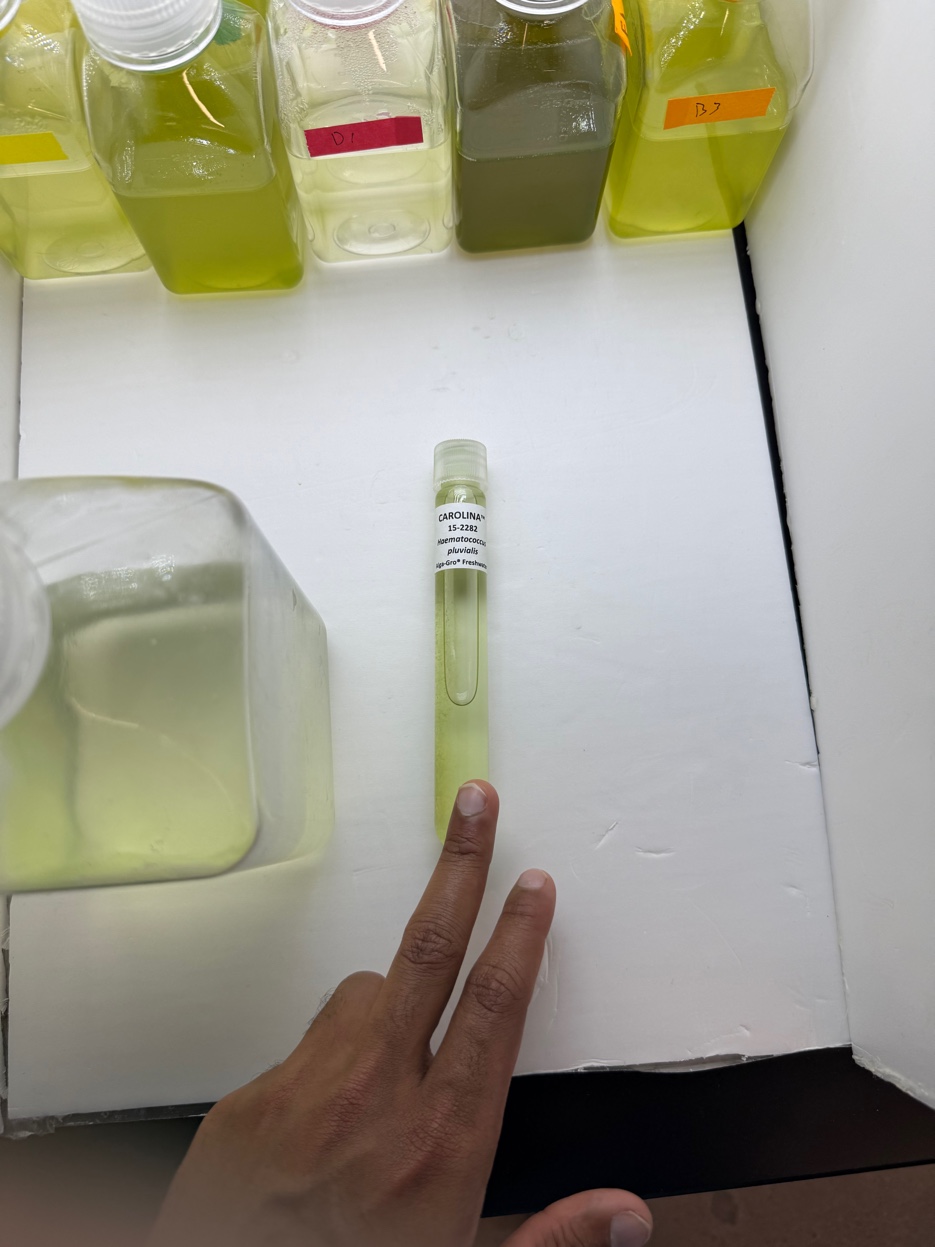

Validated with Saint Arnold BrewingThe harvested biomass contains high-value compounds. Haematococcus pluvialis accumulates 3–5% astaxanthin under stress conditions — a premium antioxidant commanding $54/lb natural vs. synthetic. Residual biomass becomes biofertilizer or biochar. And every ton of CO₂ captured generates certified carbon credits projected to reach $93/ton by 2030. Multiple revenue streams, not a single fragile product.

$0.88M/yr projected revenue (18 PBR system)AlgaZen captures CO₂ at a fraction of the cost of conventional methods — and produces revenue while doing it.

| Technology | Cost per ton CO₂ | Energy | Scalability | Additional Benefits |

|---|---|---|---|---|

| AlgaZen Microalgae | $45–65 | Solar-powered | High | Wastewater treatment + bioproducts + carbon credits |

| Chemical CCS | $150–250 | High | Medium | CO₂ storage only |

| Direct Air Capture | $600–1,000 | Very High | Low | Pure CO₂ stream |

| Reforestation | $15–50 | None | Land-limited | Biodiversity |

| Ocean Alkalinization | $50–200 | Medium | High | pH buffering |

A multidisciplinary team spanning environmental science, biotechnology, chemical engineering, physics, and business analytics.

Fulbright Scholar. B.S. Business Analytics. MSc. Environmental Analysis, Rice University. Leads strategy, investor relations, and industry partnerships.

PhD Candidate, Chemical Engineering, Monash University. Developing certified carbon balance models to quantify CO₂ sequestration — enabling carbon credit generation at scale.

B.S. Biotech Engineering. MSc. Env. Analysis, Rice. PBR design & cultivation.

B.S. Physics & Math. PhD, Systems & Synthetic Biology, Rice.

MSc. Mechanical Engineering. MSc. Env. Analysis, Rice. PBR fabrication.

MSc. Biotechnology. PhD, Systems & Synthetic Biology, Rice.

Assoc. Professor, Rice University. PI, Phytoplankton Ecology Lab. 20+ years in algae research.

35+ years serial entrepreneur & angel investor. Co-Founder, Edge of Space.

Brewery partners, investors, and collaborators — we'd love to hear from you.