Proprietary flat-panel PBR with light-guide technology.

Our patented design uses internal acrylic rods with aspherical lenses to distribute photosynthetically active radiation uniformly — eliminating the dark zones that limit growth in every conventional system.

Why light-guide rods matter

Conventional flat-panel PBRs lose 60–80% of light within the first 2 cm of culture depth. Our internal acrylic rods act as optical waveguides, channeling photons deep into the reactor volume. Result: 27% more biomass productivity and 26% more CO₂ capture than industry-standard systems — lab validated with Saint Arnold Brewing wastewater.

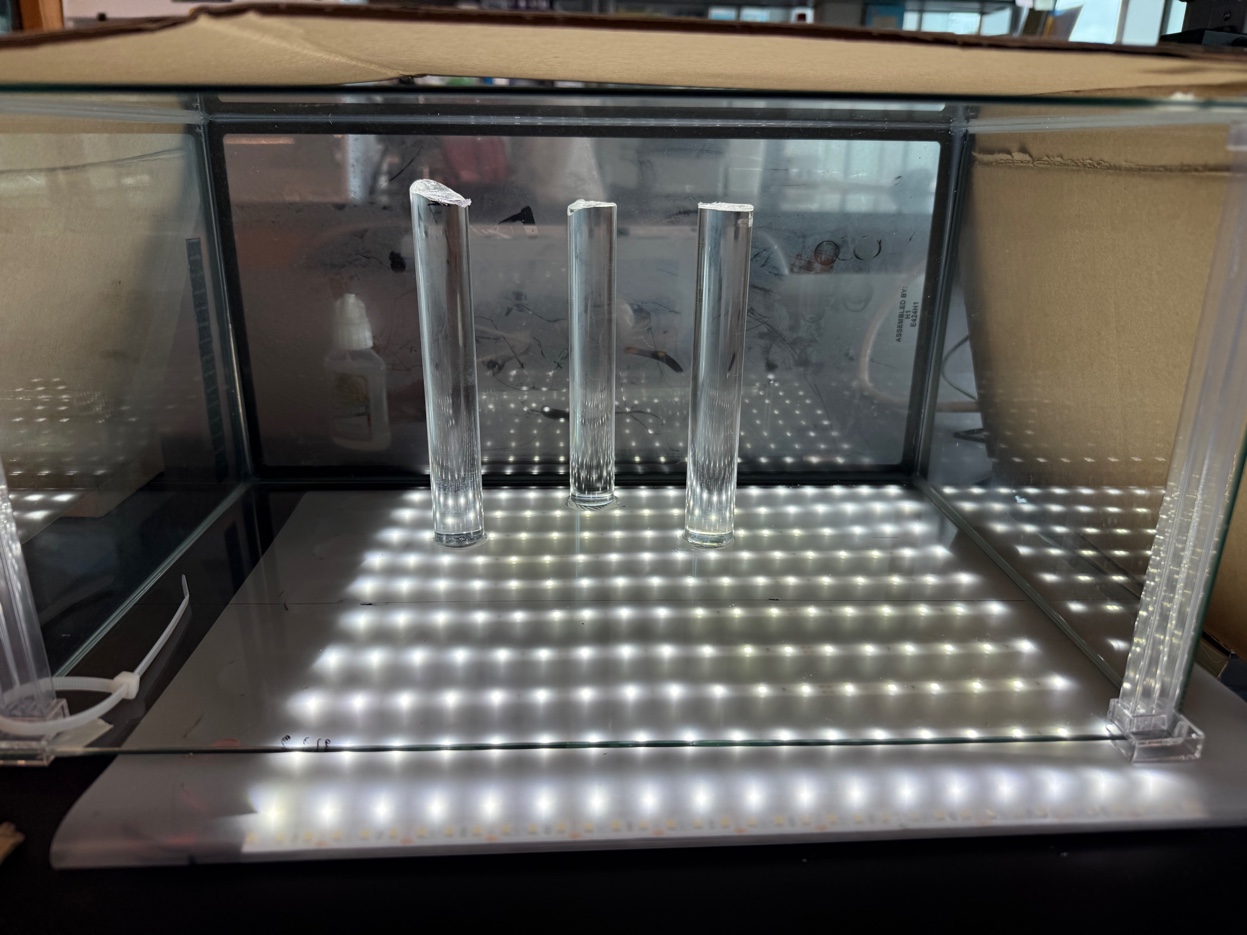

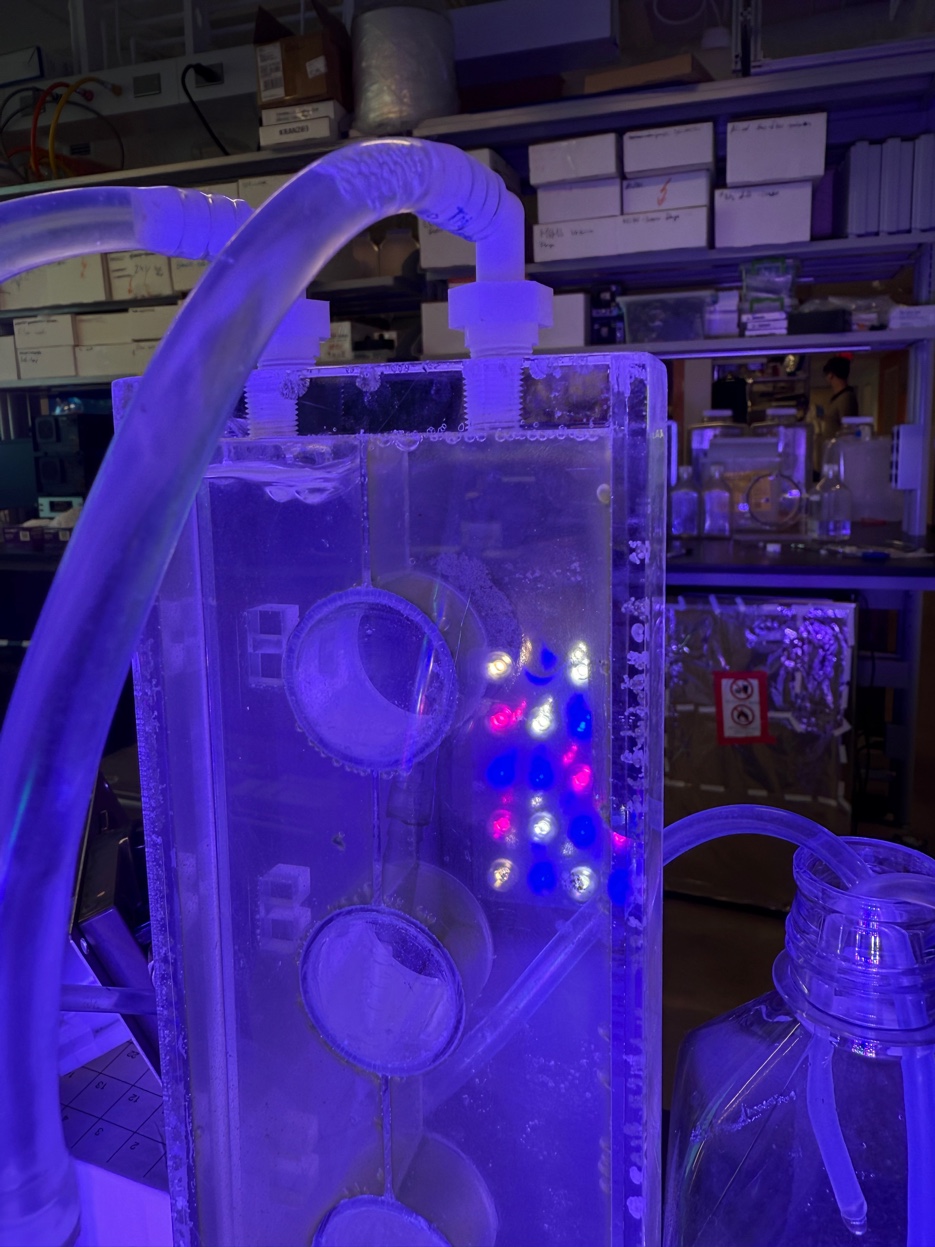

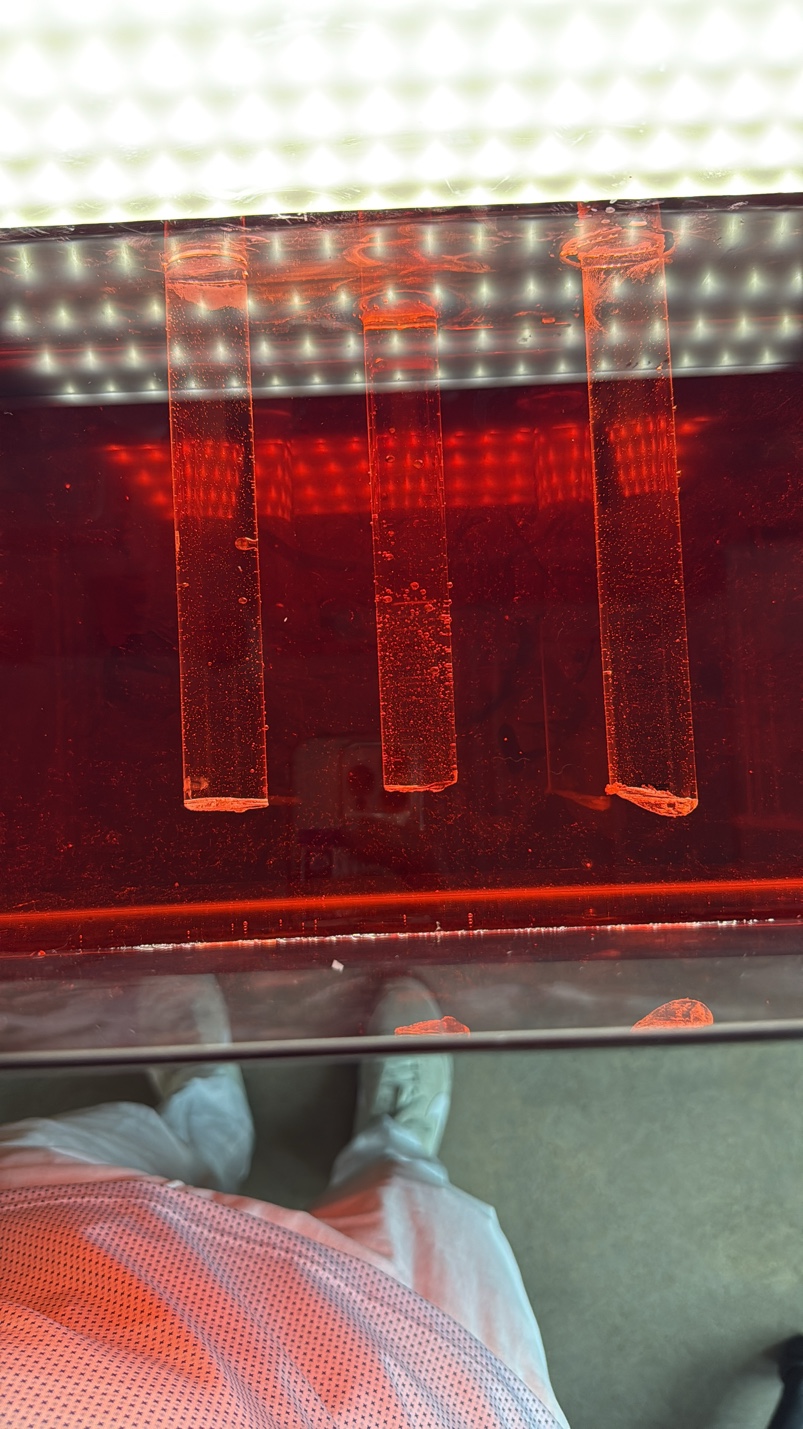

Our prototypes at Rice University — light-guide rods with LED illumination panel

Our prototypes at Rice University — light-guide rods with LED illumination panel